MacroSpan is a high performance structural system for roofs invented and developed by John Macartney. The system has evolved from a study of the principles of “Tensegrity” discovered by Kenneth Snelson, an American sculptor, and developed by the famed design scientist and inventor Richard Buckminster Fuller. Tensegrity structures are structures in which the functions of compression and tension are fully articulated in that the compression members do not meet; the compression members resist only compression forces and the tension members only tension forces under all loading conditions. They are amazingly strong and robust structures but their suitability for large scale structural systems for buildings is limited by their great flexibility. By accepting the need for compression members to meet, but only in pairs, the principle of articulated compression and tension is retained but now with satisfactory stiffness.

Through the use of these principles a structural system for roofs has been developed that can accommodate a range of shapes and is extraordinarily lightweight, strong and stiff. Analytical studies have demonstrated its capacity to span very large distances such as for stadiums, aircraft hangars and other large, column-free spaces. The structure can also be assembled on the ground and raised into position by external stressing without the need for cranes; this makes it very suitable for use in demountable mobile structures such as for emergency shelter and other buildings in remote locations.

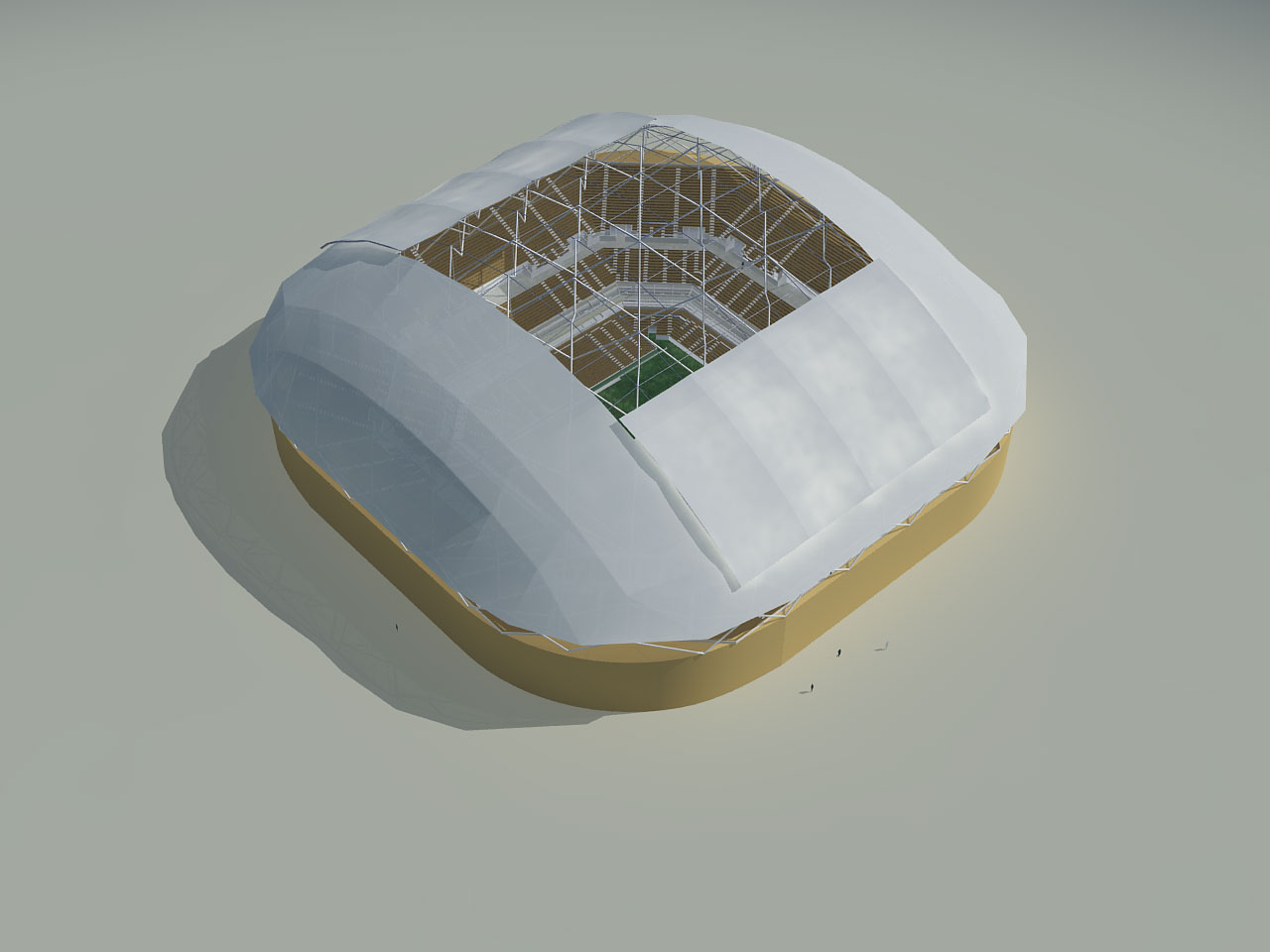

Cincinnati Tennis Stadium

The main stadium shown accommodates 15,000 people. In 2004 MEC were approached to design a retrofitted roof over the stadium using MacroSpan. The dimensions of the roof are 117 x 70 metres. The roof form used was based on a barrel vault adjusted to accommodate the rounded corners. The weight of the steel structure for the completed design including the supporting tubular steel columns is 35kg/m2 of covered area. The cladding system was conceived of as fabric with retractable panels over the court. The erection procedure planned comprised installing and temporarily bracing the perimeter columns, erecting two tower cranes at the 1/3 points on the main axis of the roof, installing the main tendons spanning in catenary from the perimeter columns to the tower cranes and then installing the main struts moving out radially from the tower cranes to the perimeter. The structure would then be stressed to the required design levels to achieve precisely the correct geometry then the temporary bracing to the columns removed. The tower cranes would remain in place for the installation of cladding and services then be dismantled.

MacroSpan Transformer

Isometric Full Assembly on Ground

Isometric Full Assembly Erected

Whilst the Cincinnati Stadium exploits project the spanning capability of the system, MacroSpan Transformer makes use of the MacroSpan’s attributes of ease of assembly, erection, lowering, disassembly and relocation in manageable component sizes. These attributes can be used cost-effectively for buildings ranging from simple shelters up to large, column-free industrial sheds. A design has been prepared for a small shelter, approximately 8 metres wide when erected, for use as emergency shelter in disaster situations. The shelter is a complete building system with roof, wall and floor structure, cladding and services. With the aim being to make this application of the system as self-sustaining as possible, power is provided through solar panels, water through the collection and storage of roof run-off in tanks located immediately under the roof and sanitation through composting toilets. For the example shown the heaviest building component weighs 12kg. The building is assembled entirely on the ground and jacked up into position using simple manual jacks.